Silica sand - Mould making Process

As we know that metal manufacturing companies uses a sand

mould to shape melted metal. It is a process that dates back centuries, but

still this basic process is not changed because it is inexpensive. Foundry sand

is essential to metal casting industry. Silica sand is compatible for mould casting because of the high union point and

low rate of thermal expansion. Once the mould casting process is completed, the

silica sand mould is broken into parts and sand is recycled to make new mould.

The basic Principles of sand casting have not changed over

the year. The idea is to 1. Mix silica sand and water, 2.pack the sand into mould,

3. Press a model in the sand so that mould can be made. Mould sand mixture is

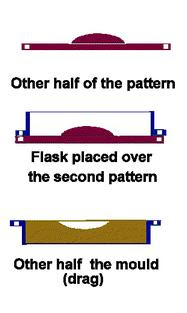

depends upon the type of the metal which has been cast. The mould is divided

into two parts one is upper half is called cope and another one is bottom half

is called drag.

How the mould is made from sand

* Already designed pattern is placed into mould.

* Half fill the mould box with sand (mixture of sand and

water) and press the sand evenly, so that the pattern is printed on the sand.

* Same step is repeated for second half pattern.

* Lubrication is also applied to the surface of the mould.

Lubrication improves the flow of the metal and improves the surface of the

final part

* Clamped mould is filled with the molten metal is called

pouring and leave for it to set.

* Remove the clamp and put the sand mould to vibrate table. It

shakes the mould and removes the dust from the final part.

Photo credit: google.com

0 comments :

Post a Comment